There are many bad things that can happen to a boat. Earth (running aground), water (sinking) and air (wind and lightning) are all enemies to our floating home. Right now it was water that was threatening us. As we motored away from the Krka river, a hideous, high pitched squeal had emanated from inside the boat. We stopped the engine and hurried inside to investigate. The noise had stopped with the engine pause, but an acrid smell of burnt rubber took its place for hideousness. The smell was worst in the aft cabin, where the propeller shaft enters the boat. Lifting the floor, we found that Emerald’s propeller shaft was burning hot.

The Unfortunate Necessity of Holes in a Boat

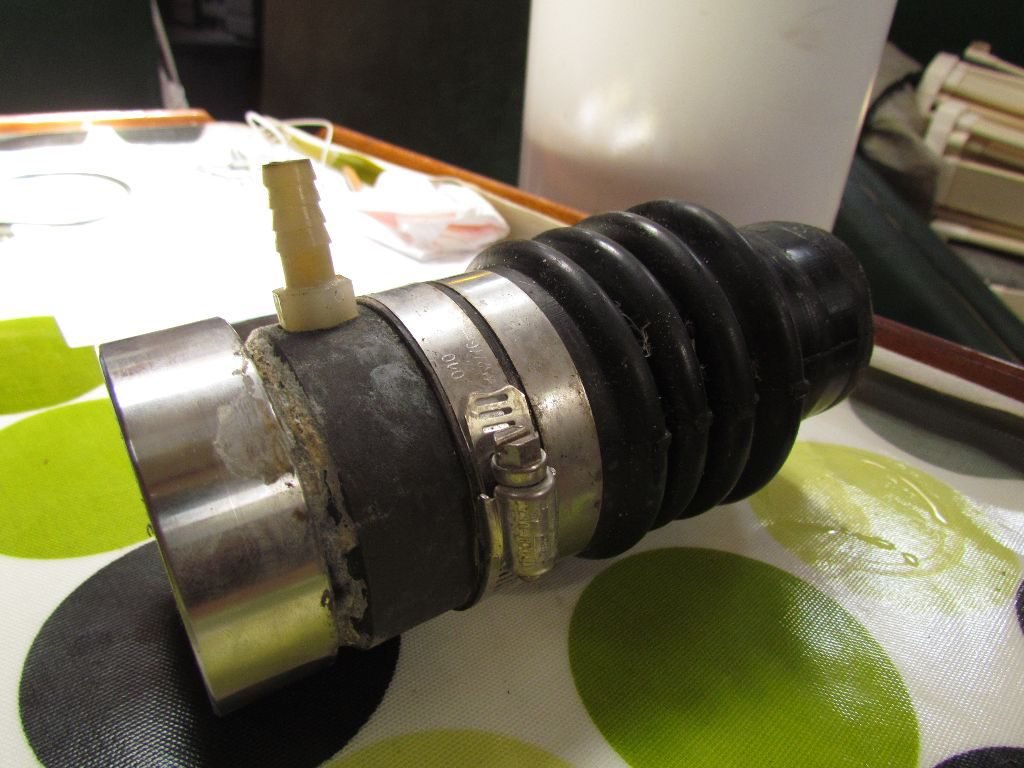

Ideally we wouldn’t have any holes in the hull at all. But unfortunately there is a need for water to come in and cool the engine or to flush the toilet and for waste water to go out. The propeller shaft also needs a hole to allow it to attach to the engine. Around the propeller shaft are two cutlass bearings and a shaft seal that in theory keep any water out.

As the prop shaft spins, things get hot. Hence the shaft seal has a water feed to keep it cool. Our guess is that either the bearings or the seal had failed creating debris that blocked the cooling pipe. From there the heat increased and rubber began to melt. This subsequently damaged the seals even more and allowed water in along the shaft. As a result, water was now dribbling into the bilge.

Limping to Safety

Colin was able to slosh away the debris and reestablish the cooling water flow to the shaft. This meant we were able to run the engine at low revs and limp on to a safe anchorage. There we hoped to have a better look at things. So, in a large bay we dropped the anchor and began researching the recommended fixes for the shaft seal. The internet signal was slow, which didn’t help our fraying nerves. However, despite our best efforts, the damage was too great and we couldn’t stop the water flowing in. We would need to lift Emerald out of the water to replace the bearings and shaft seal.

By now it was Saturday evening. Our new worry was where to go, as we had zero knowledge of boat yards in Croatia. Would we be able to live aboard and do the work ourselves? We started contacting the local yards, sending emails when we found that offices were closed as it was now outside of a working day. We wouldn’t be getting any reassuring confirmations for a lift out that day.

Two Sleep Deprived Nights

Water gets in to the boat in every day use in various ways. When it rains we have a few leaks or if we overfill a water tank. Wherever it comes from, it runs to and gathers in the lowest part of the boat which is the bilge underneath the engine. In the bilge there is a switch that triggers when the water reaches above a certain level. It sets off a pump which then sucks the water out and sends it out to the sea. As a backup we can also manually suck the water out with a hand pump into a bucket. To give you an idea of the rate of leak: we were filling a 10 litre bucket an hour. This was a similar amount of time between triggers of the bilge pump switch.

So we had a sleep deprived and anxious night. The bilge pump woke us every hour. We also set an alarm set for every two hours in case the pump failed. We really didn’t want to be paddling when we got out of bed the next morning.

On Sunday morning we decided to move an hour north to be nearer two marinas in the town of Murter. One of them had confirmed they could lift us Monday morning. So we just had another worry filled day and sleepless night to get through, hoping that the leak rate didn’t increase. We contacted our insurers who backed our plan.

Lifting Out At Murter

As it turned out the delay was a sort of blessing in disguise. It gave us time for more research and time for friends to get in touch. We received a suggestion for another yard in Murter which could be better suited to us. So, first thing Monday morning we made contact. Yes they could lift us but we just had to wait for the wind to ease a little. It was a restless wait, watching the wind meter closely. Colin took the opportunity to dinghy over to have a chat with the yard and check where we needed to go.

Safely on the Land

By midday the wind had eased and boats were being launched. Very soon it was our turn. The wind was still gusting F5 and we had to go into the narrow lift out area backwards. Emerald doesn’t do backwards very well. Several failed attempts had my stress levels rocketing. But then we caught a break as the wind dropped and we were going in almost the right direction rather than spinning around to port. The yard guys had clambered out as far as they could get onto the boats on either side of the slip. Colin threw a line to them and a combination of reverse and pulling on the lines got us where we needed to be.

We clambered ashore and shortly afterwards Emerald was lifted free of the water. A blast with the pressure washer got rid of the unwelcome underwater growth. The guy doing the pressure wash, pointed out the bar could be a good place to wait. But where was the bar? All we could see was a shipping container. Like an oasis in the desert, nestled inside was a homemade counter, with two ladies and a fridge behind it. Accompanied by big smiles, the ladies handed us two cold beers for the bargain sum of just E1. Never was a beer more welcome!

After restoring our equilibrium we headed outside to find Emerald securely chocked and settled into her spot. She was ready for work to begin.

Worse places to have a lift out. Krka is lovely.

Hope you get a nice smooth bottom and your rubber sorted soon.

Paul

Good luck thanks for all the tips and updates, in the process of renovating kp 44 # 146 there’s a lot of little items as well as a few large numbers to work on, the shaft had been replaced but no knowledge about upper bearing

Hi Andre, good luck with the renovations, if you have any questions please ask.