“Are you feeling excited or nervous?” I asked Colin as we left the harbour office on a Monday afternoon, having made the arrangement for Emerald’s launch tomorrow.

“Both” he replied. “Me too!”

We learnt that it is possible to feel so incredibly excited by a moment whilst at the same time feeling absolutely terrified. Emerald’s launch would be the moment when we would learn whether all our work over the last year was good or not.

If everything went well we’d be floating not just on water but also on a euphoric high, celebrating the successful completion of what at times felt like an impossible ask. Or, it could end in failure, with a sad return to the boatyard and an even longer postponement of our dreams. I tried not to think too much of the former in fear of jinxing it, whilst being absolutely terrified by the latter.

But we didn’t have too much time to dwell on the bad as we now had to cram two days of final prep into half a day. But more on that later.

The Coppercoat Repairs

Before we get to the moment of truth, we rewind a week or so to when we were closely watching the weather as we prepared to complete the last job before launch. The Coppercoat needed some small repairs, but the arrival of distinctly autumnal weather had tested our patience for a couple of weeks. Then on a Saturday, storm Bernard blew right over us, bringing very strong winds and heavy rain.

As the storm passed, we saw a possibility opening up for the following week. On Sunday it was still looking good for the next few days. We needed a day for preparation, and a day for painting. The forecast indicated rain on Thursday evening which would allow us just about the recommended 48 hours of drying time.

Why Did we Need to Repair the Coppercoat?

We’d only applied Coppercoat in April 2022, and Emerald had spent most of the time since then on the hard. However, whilst washing the hull, we’d noticed an area about 1 meter long by half a meter wide of raised bubbles on the port side bow. With some trepidation, we closely inspected the rest of the hull. We were relieved to find that the bubbles were confined to just that one, small area. All we can assume is that there was some form of contamination during application, either on the hull or on the roller.

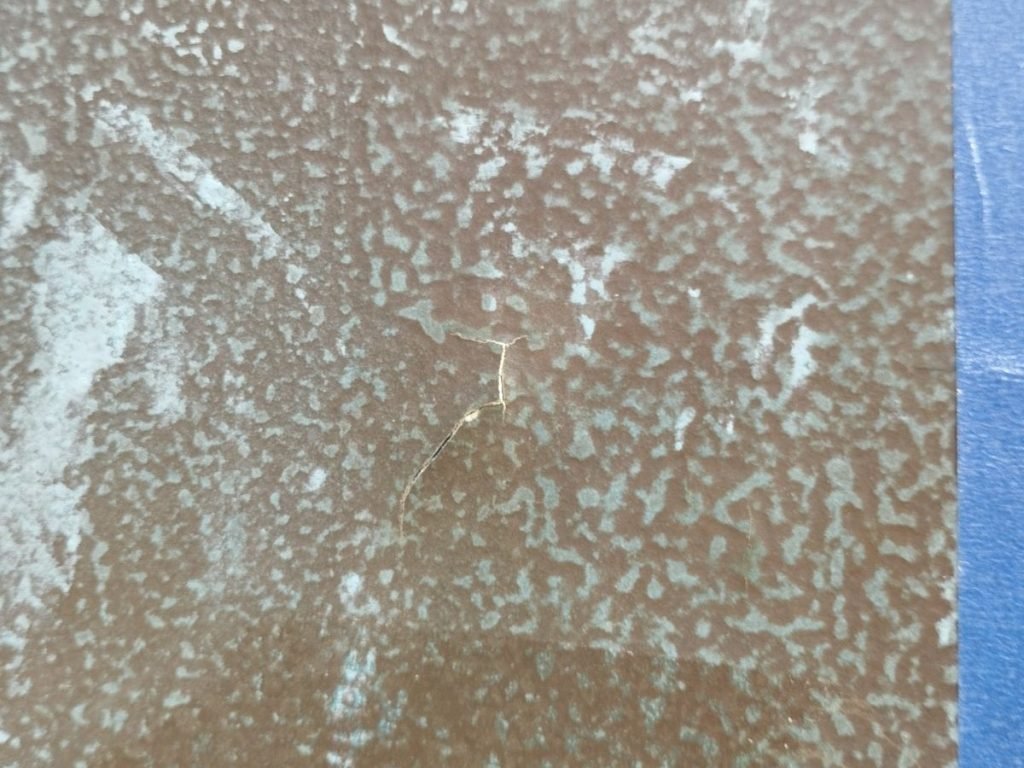

But later during our time on the hard, a 2cm crack had also appeared just below the waterline. Perhaps something had hit the hull during strong winds?

The crack turned out to be worse than we’d thought. The damage started in the layers below the Coppercoat, down in the old gelcoat that had formed the old waterline. Emerald has a very thick hull, and after sanding, we’d only removed a thin layer of fibreglass. So we patched it up and we’ll keep an eye on it.

There were also the areas around the four new through hulls that we’d recently fitted. We’d had to remove a circle of Coppercoat to ensure that the TruDesign through hulls bonded properly with the hull.

Good to Go

With the preparation work of sanding, cleaning and taping up complete, we woke up early Tuesday morning to check the weather forecast again. Thursday’s rain had moved a little forward, but with the warm air temperature the coating should have time to dry before it arrived. It was a go for the painting.

We only had a half pack of the Coppercoat – 250ml of each part of the epoxy mix and a kilogramme of fine copper powder.

I used the same technique as when we painted the whole hull to prepare the components for 5 coats. First, I split each liquid into 5 identical, clear plastic cups. To mix, I simply poured the orange part into the white and stirred it thoroughly. Next Colin slowly added the copper powder as I stirred it in. We finished off with a dash of isopropyl alcohol and another very thorough stir.

The whole lot then went into a small paint tray and Colin got to work with a small roller. He also used a brush to paint the inside of the through hulls. The painting took less than 15 minutes, we then had to wait almost an hour before applying the next coat.

We were finishing by mid afternoon and cleaned up. A job well done.

Argh! It’s Raining on our Coppercoat!

Around 10 o’clock that night I heard some soft taps on the deck. Surely it wasn’t raining? The forecast hadn’t shown any until Thursday! But unfortunately when we looked out our hearts plummeted as we saw a fine drizzle coming down. We rushed out to see what we could protect and set up a tarp over the larger patches on the bow. The seacock areas were under the belly of the hull, which would give protection. But there was nothing we could do for a couple of patches along the waterline other than hope.

In our favour, the rain didn’t last too long. But it was with some trepidation that we went below the next morning to see what the damage was. What a relief to see no visible runs or discoloration.

The same happened again on Wednesday night, but this time the rain was more prolonged. Our hearts sunk again. The coating had still been slightly tacky in the evening and was still at risk of damage.

In a repeat of yesterday, we made our way down the next morning, hoping that the Coppercoat was unscathed. It was! What a rollercoaster of emotions.

In more good fortune, Thursday’s rain didn’t materialize. By the end of the 48 hours after application, the Coppercoat was still very slightly tacky but intact. By Friday it was fully hard.

Next We Needed a Launch Window

With the Coppercoat repairs completed we could look for a window for launching. We told the harbour manager “next week” and began a frenzy of cleaning, stowing and preparation for Emerald to go back to sea.

We’d been aiming to launch on Wednesday, where a forecast of barely any wind and sunshine sounded ideal. But we’d forgotten that the 1st November is All Saint’s Day and a public holiday in Portugal. In the office, we quickly scanned the tide times and weather, looking for the next best alternative. High tide was in the afternoon, getting later as the week went on. By Thursday we wouldn’t be launching until late afternoon, which didn’t leave much scope for solving potential problems. Some wind was forecast for both days. But the bad weather on Monday into Tuesday was showing as clearing by midday. We went for Tuesday 2pm to fit with the tide.

However, we now had to squeeze two days of final jobs into just half a day. Perhaps it was a good thing as it left little time for worrying.

As expected, Monday night and into Tuesday morning it rained and the wind blew. We’d washed the decks but by morning there were more piles of grit on deck, gathered up against the stanchion bases. It’ll take a week of heavy rain to fully clear the rigging of the Porto Santo dirt.

The Boat Lift is Coming for Us at Last

On Tuesday morning the rain cleared as expected but the wind took longer to ease. At 11am we were watching our NASA Meteoman still displaying 20kt gusts. They wouldn’t launch us if it didn’t ease off. But, fortunately by midday the gusts abated and a last check confirmed we were good to go.

Emerald has spent the last 15 months parked in front of the shed where the boat crane is kept. We’d become very familiar with the beeping sound that it makes every time it moves and named it Bertrand le Beep. We’d enviously watched other boats leave, but at last Bertrand was coming for us.

The crane has two strong steel arms that sit above either side of a boat. Descending from the arms are thick wires that fasten to two canvas straps. These straps go under the boat’s hull and support it as the crane travels along the ground. Because of our solar arch and because we chose to put Emerald backwards into the crane, there was very little clearance between the ground and Emerald’s keel. We watched anxiously as the lift straps took the strain and the supports were taken away, but the clearance was enough.

Sadly, as the supports came away from the hull, two of them pulled some of the Coppercoat off. Emerald had been in the supports for so long, that it seems that the pads had stuck. We kicked ourselves for not having had Emerald moved in the stands before we repaired the Coppercoat last week. We do keep learning lessons the hard way.

Heart in Mouth Moments

It’s an anxious moment for boat owners, seeing your pride and joy dangling just above the hard, unforgiving ground. However, for us, the worry didn’t stop even once Emerald was floating again. There was still a very long list of things that could go wrong.

Firstly, there were the four seacocks that we’d recently replaced. We’d tested the interior joints for watertightness, but we couldn’t test the seal between hull and through hull until we were in the water. Having had a problem with one joint, this issue played heavily on our minds.

Secondly, there was another hole in the hull that had had some attention whilst in the yard. The rudder stock is a metal tube that connects the rudder to the steering quadrant. It comes up under our bed in the aft cabin. To prevent water also coming in, it has cotton wadding and grease stuffed around it. We’d replaced all of the old wadding and grease with new, but as with the seacocks, there was no way to test if we’d added enough until back in the water.

Third, the propeller shaft, yet another hole in the boat through which water can get in. We’d had to move the propeller shaft to have the engine lifted out and had taken the opportunity to refurbish the shaft seal.

Then last, but by no means least, there was the engine. We’d tested it in the summer and had started and run it briefly last week, but we hadn’t been able to test putting it in gear with the prop shaft connected. Would it start and could we drive away?

The Moment of Truth

With Emerald hovering part in and part out of the water, we climbed aboard and the crane lowered her the last short distance into the water. We were floating! But there was no time for celebrating. The launch slipway is narrow and there was a very slight swell coming in, so we wanted to get away from there as quickly as possible. Colin immediately went below and starting from the stern, checked all the possible leak points. We’d opened up as many of the spaces as possible to save time, but he still had to lift out the companionway steps and remove the galley floor to check the seacock under there.

I nervously remained on deck, trying to hold Emerald off from the rough sides of the slip. We had fenders out but even the gentle swell was moving her around in ways that weren’t good. I noticed too late that the wire cables of the straps were sawing against the teak cap rail. Unfortunately the wires took out a couple of chunks of wood before I was able to push them away.

Finally, Colin looked up from below and gave me the all clear. I immediately started the engine, willing the glow plugs to heat up faster than usual to get us away before there was any more damage.

We’re Motoring Away

The seconds seemed to take forever, but eventually the plugs were warm and I put the engine into gear for the first time since the rebuild. We thankfully began to move forward and away from the slipway. As we motored off the yard guys gave us a big wave and looked so happy for us. I felt the tickle of tears of happiness, but quickly dashed them away.

Amazingly, there were three free moorings for us to choose from. Just two weeks ago the inner harbour had been completely full, with all the moorings taken and limited space in which to anchor. Good for us, it had thinned out considerably as many boats headed off south to the Canary Islands. Maybe the bad weather that delayed our Coppercoat application had been a blessing in disguise.

I drove Emerald carefully out beyond the mooring field, keeping a good eye on the engine oil pressure, temperature and voltage gauges. We wanted to be away from the other boats as soon as possible, in case the engine gave up and we had to quickly drop the anchor. But so far, so good, all the engine readings were within normal range so we could make our way back in.

We motored around to our first choice of mooring, but as we passed by another boat, they called out to us that it was damaged. So, onto our second choice. We’d asked a friend to dinghy out to help us pick up the mooring, it’s been so long since we last did this and we wanted everything to be as easy as possible today.

Time to Stop and Savour the Moment

Emerald’s launch had been so frenetic that we hadn’t had any time to really think about what we’d achieved. But now, with Emerald safely attached to the mooring, we could stop and take things in. We checked the bilges again and everything was still bone dry – so no leaks! The engine had performed marvelously, we even suspected that it was running slightly quieter than before.

We stood on deck and gave each other a huge hug, our bodies quickly adapting back to Emerald’s gentle movement as she bobbed on the sea. Looking around, we soaked up the view from a perspective that we hadn’t had for so long. We’d really done it! We’d successfully repaired and rebuilt a sea water damaged engine. Those moments when the engine repairs had seemed insurmountable will leave scars in our mind, but the feeling of being back where Emerald belonged was amply salving them.

Our sailing life has been on hold for well over a year but at last we could begin to plan our next adventures. Where would we go next?

The Social Media Bit: Want to Follow Us?

If you’d like to follow us on other social media platforms (Facebook, Instagram and YouTube), you can do so by using these links:

Or use the link below to track our voyage on NoForeignLand.com.

And finally, you can sign up to receive email notifications of new blogs using the subscribe box at the bottom of this page.

Thank you from Nichola & Colin

Well, that didn’t take long .

Seriously, well done to you both. You certainly have stamina.

Missing those thirsty swallows…

Duncan

Thank you, our stamina bucket is very, very empty now. We miss the thirsty swallows and both of you!

wow! it has definitely been a lot of work and strain on you physically and mentally I’m sure but so glad that things came together and that you are afloat now! congratulations! Will look forward to finding out where Emerald will take you next!

Thank you Janice, we’re certainly looking forward to new adventures

I know I will be one of many who is whooping with joy at reading your latest blog…recovering from the depths of adversity ….you are both inspirational… 🙂

Thanks Phil, we can here the whoops from here 🙂