We had arrived after a boisterous sail from mainland Portugal to the island of Porto Santo. However, on approach to the island, the engine had failed to start. We’d managed to sail into the anchorage outside the harbour, where further tests indicated we definitely had a broken engine.

After a good night’s sleep we felt more ready to face the horrors. First things, to get Emerald into a safer location. The anchorage off the beach at Porto Santo seemed OK, but if we did drag, it would be next stop Canaries. Or maybe Brazil. Sailboats are made to move with the wind, but in close quarters, such as a marina, an engine is essential. So, our broken engine meant we couldn’t manoeuvre Emerald safely into the harbour. We thought about towing her ourselves with the dinghy, but at 8hp, the outboard just isn’t powerful enough.

We launched the dinghy and went ashore to visit the harbour office who were able to offer a tow at a reasonable price and arranged to be with us at 2pm.

The Tow

The tow arrived early, but we were ready. Thank goodness it was a day of light winds, because even then, Emerald proved how obstreperous she can be at times. We had to give up on a tow from the bow, and tied up the work boat alongside instead. As we lifted the anchor, Emerald turned her bow away from the harbour. Cue our first pirouette. After that the tow settled down and with Nichola steering we made it safely through the harbour entrance.

It wasn’t busy in the harbour, but even so, we didn’t want to be threading our way through other boats when we had limited manoeuvrability. We also needed to be inside the yellow buoys that limit the ferry turning area. As Emerald made another pirouette, it was quickly decided to place us at the back of the anchorage area. We had just enough space to drop sufficient chain for the depth, whilst keeping us within the buoys.

Broken Engine Island

It wasn’t just us suffering from a broken engine. The week before our arrival, a Swedish boat needed a tow in after their engine failed. Their high pressure injector pump had to be sent away to Maderia for repairs. A catamaran also had problems with one of its engines. Should Porto Santo be renamed broken engine island?

The remoteness of the place itself was a big concern. On an island of less than 6,000 people, would we be able to find the resources and help we might need? We carry a lot of tools and spares on Emerald, but if we ultimately needed a workshop, what would we do? We pushed those concerns aside temporarily as there were actions we could get on with ourselves.

The Fuel Lift Pump

When we had tried to start the engine on our approach to Porto Santo, Colin had noticed that the oil level was very high. Having extracted some of the liquid from the sump, our assumption was that diesel was mixed in with the oil. There were no indications that it was water. This led us to think that the fuel lift pump had potentially failed. The fuel lift pump ensures that the fuel injector has enough fuel at the correct pressure. If it leaks, the diesel drains into the oil sump. With Emerald heeled to port, the starboard diesel tank would have been higher than the pump. If the pump diaphragm was damaged, the pressure of a full fuel tank could have pushed diesel through it and down into the sump.

We carry many spares on Emerald, one of which was a fuel lift pump. We’ve carried it around since 2006 when the engine was installed, was it now about to prove its worth?

Draining The Oil

We would normally do an oil change with the engine warm so that the oil flows smoothly. Of course, without a running engine we couldn’t do that. So, it was a slow process over two days to drain the sump of oil and the extra 2 litres of stuff. The oil extractor pump didn’t help matters either. We’ve been saying we’ll buy a new one for ages, but hadn’t got around to it. So Colin had to MacGyver an O-ring fix so that it maintained the pressure, otherwise it could have taken days to get the liquid out.

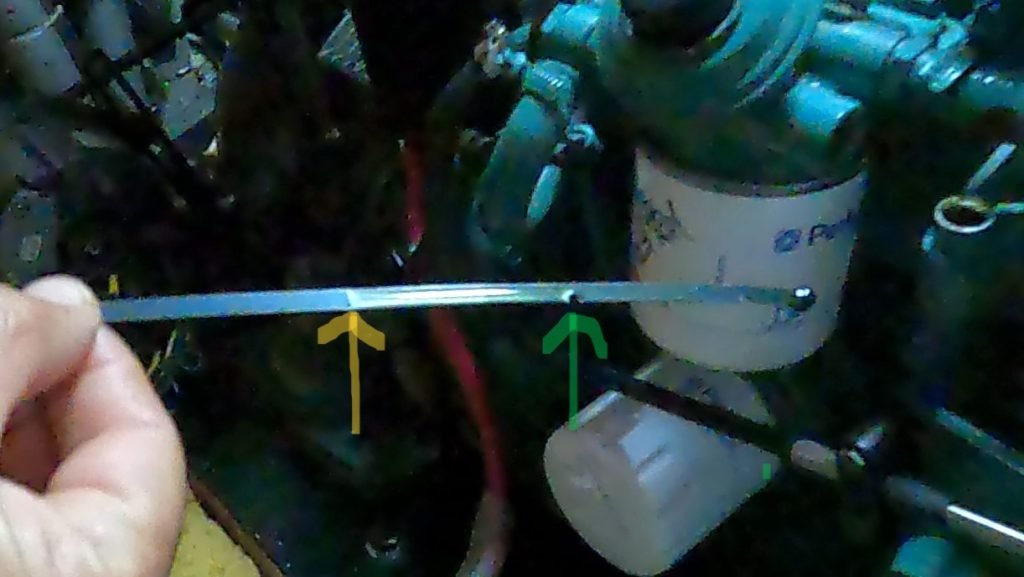

Next was the removal of the old fuel lift pump. The engine designers don’t make it easy. Access to the bolts was extremely difficult, especially when taking into account the space needed for a spanner and for it to be able to turn. But eventually it was off. On inspection there didn’t seem to be obvious damage other than some creases in the diaphragm. But maybe that was enough?

Installing the new pump was even more difficult than removal. There may have been some extreme cursing of engine designers at this point.

New oil filters came next, we also carry plenty of spares of these. But in the process Colin discovered the fuel bleed screw had snapped, with part of it left in the hole. So, he had to remove the oil filter cap to allow access to remove the broken part of the screw. Why is boat maintenance never straight forward? We didn’t have a spare bleed screw, but Colin made a temporary replacement using a stainless steel threaded screw from our stash.

Will The Engine Start?

We were now ready to try the engine again. But given that it was late in the day, we decided to put it off until tomorrow.

Schrodinger’s Engine

It’s hard to explain how anxious we felt at this stage, and that by not starting the engine, we would have a few more hours of hope. We had dubbed it Schrodinger’s engine – until we tried to start it, the engine was both “dead and alive”.

A few hours delay would also allow time for the fresh oil to trickle around where it needed to go. Well, that was our excuse.

The next day we knew we had to give it a try, and after all it could be good news. We checked everything that we would usually check before starting the engine, plus a few other things. Colin sat by the engine to observe, I went out into the cockpit to set the throttle, then turned the starter key. But we didn’t hear the welcome thrum of the engine, just a click, then a brief cough. We tried again with the power source set to the house bank. Same result. Click, cough.

The engine did however turn further than previously. Rather than just a click when we’d turned the starter, we now got a cough. We marked the crank pulley and filmed it to see if it made a full revolution. But it only turned the equivalent of the movement of two pistons. We were able to turn it further by hand, but it was obvious the pistons were not moving freely.

A Welcome Distraction From a Broken Engine

That afternoon, we received a message from friends on Amokura saying they’d arrived in the harbour but were leaving tomorrow. Would we like to meet up? Of course! This is one of the great things of the sailing life – reconnecting with friends that you haven’t seen for ages. We met during a winter in Marina di Ragusa, and had last seen them in 2017 in Greece. A catchup over a few drinks was a very welcome distraction from the engine woes.

Is It an Electrical Issue?

But sadly there was little respite from the engine. What next? Our thoughts turned to whether it was a problem with the electrical system. We’d only replaced the starter motor 18 months ago, but it could have failed again. With some difficulty as it is located on the far side of the engine, Colin removed the starter motor and bench tested it. Everything passed. We checked the starter battery voltage and tried starting on the house bank too. Next, we swapped the relays in case one had failed. But still with the same result.

It seemed unlikely to be an electrical issue.

Checking the Exhaust System

Next was to check the exhaust system. Emerald has a water lock box that is located on the floor of the engine bay. It connects at one end to the exhaust elbow, and the exhaust hose at the other. Its purpose is to prevent water back washing from the exhaust hose to the engine. As Colin removed the exhaust hose from the water box outlet, a lot of water gushed out. Was there too much water or was that to be expected? We really didn’t know.

Bringing In External Help

At this point we knew the next step was to remove the injectors and inspect inside the engine head. But we’d reached the limit of what we could do ourselves and the time had come to call in help. There was a mechanic at the marina, who was recommended to us. He arrived after work one evening and began removing the injectors. Unfortunately we had every sized spanner but the size we needed, but a neighbour boat helped us out. But progress stopped when he needed a different sized spanner that neither us nor the other boat had. He arranged to come back tomorrow with his tools.

The intention was to see if there was water in the engine head. With the injectors out, when we turned the engine any water would spit out through the holes. But when we turned it, nothing came out. This was good really, it meant there was no water in there now. But it didn’t tell us whether there had been water at some point. This clue came from specks of rust on the injectors, which was not a good sign.

Salt Water in the Engine

The reality was that salt water had got into the engine. The fuel lift pump had been just a distraction from the main event. Whilst we had been fixing that, the salt water had been doing its worst: corroding the cylinders, rings and fittings inside the engine head.

The Lowest Point

Saturday was our lowest point. Maybe it was something lost in translation, but the engineer seemed to indicate we would have to replace the engine. My heart sank.

We were facing the difficulty of finding a replacement engine whilst stuck on an island with limited transport and resources to help us. And that was besides the costs which would take a huge chunk out of our savings. It was extremely difficult to remain positive as various disaster scenarios ran through our head.

A big concern was where would we go to do the work? Could we stay in Porto Santo? The boatyard was currently full, but we could wait for a space. But would we find help here? It seemed this was unlikely, given the information we’d received so far. Madeira has a boat yard, but we couldn’t live aboard there, which would vastly increase our costs.

Maybe we could get back to mainland Portugal? Friends offered to meet us offshore and tow us in, but we would need to wait for a break in the north east winds which typically come in the autumn.

Would the Canaries be better? The sail there is only 2 days and downwind. But when we contacted a number of yards there, they were either crazy expensive or full.

If we needed a new engine, how long would it take to arrive? Where would we order it from?

Did we have the motivation to see this through? The last year in the boatyard had drained us and the question of selling the boat obviously came up. Was this the straw that pushed us over the edge?

So many questions without answers overwhelmed our brains. We numbed them temporarily with a few glasses of the local rum.

A Better Frame of Mind

We woke the next day in a slightly better frame of mind. Colin’s friend John had allayed some our fears and encouraged him to do the work himself following John’s remote expert guidance. Of all the systems on the boat, the engine is the one we have least confidence in our abilities in. We’d never done anything like this before, but what was there to lose in trying? After all, we already had a broken engine, and it would remain broken if we didn’t do something ourselves.

Over the next few days we researched and reached out with questions via social media. It has its negatives, but in times of need, the available networks can make a huge difference. The guidance and information we received helped settle some of the big doubts and the black clouds began to dissipate. The sailing community supported us with tales of similar situations that in the end were got through.

We cannot say thank you enough to John, our friends and the sailing community for helping us with support and well wishes.

What Next?

What happened next is that Colin took the broken engine apart to expose the cylinders within the head. The intention was to see how bad the damage was and get them moving again. We’ll save that for another blog.

So How Did We End Up With a Broken Engine?

How did sea water get in to the engine? We’ll never know for sure, nor know when it happened during the three day passage.

We’ve travelled over 18,000nm in Emerald, and this has never happened to us before. We’ve experienced several occasions with big following seas – in Norway a F9 chased us out of the Skaggerak with green foam blowing off the crests of the waves. On the last day of our Biscay crossing in 2013 we had similar conditions to our passage to Porto Santo, with a swell forecast for waves of 2.5m. This is similar to what we’ve experience in the Med whilst riding on the end of a mistral from the Golfe de Lion. So, nothing that extreme.

Which makes us think it was an unlucky, perfect storm* of events. Forecasts only predict an average, so perhaps a larger, powerful wave broke against the stern at the same time as Emerald rolled in a particular way. As it hit, the wave water would have entered the exhaust hose. Maybe the volume and force of water was then enough to overwhelm the water lock and as the boat rolled or fell off a wave, it was pushed into the engine via the exhaust.

An alternative theory is that the water entered up the raw water intake. The inlet for this is on the starboard side of the hull and with Emerald heeled over to port, the seacock could be vulnerable to the waves. But we have a syphon break, set at the top of the engine room, whose purpose is to stop this happening. So this possibility seems less likely.

The Perfect Storm?

* The Perfect Storm is the name given to a huge storm that hit north east America in 1991. It led to the sad loss of the fishing boat Andrea Gail, with all hands. The boat was based out of Gloucester, Massachusetts. When we bought Emerald, she was moored at a place called Eastern Point Marina, which is at the outer end of the bay with Gloucester at its head. We don’t think Emerald was moored there back in 1991, but we’ve taken this connection with where we bought her to describe the unusual events that could have scuppered our engine.

The Social Media Bit: Want to Follow Us?

If you’d like to follow us on other social media platforms (Facebook, Instagram and YouTube), you can do so by using these links:

Or use the link below to track our voyage on NoForeignLand.com.

And finally, you can sign up to receive email notifications of new blogs using the subscribe box at the bottom of this page.

Thank you from Nichola & Colin